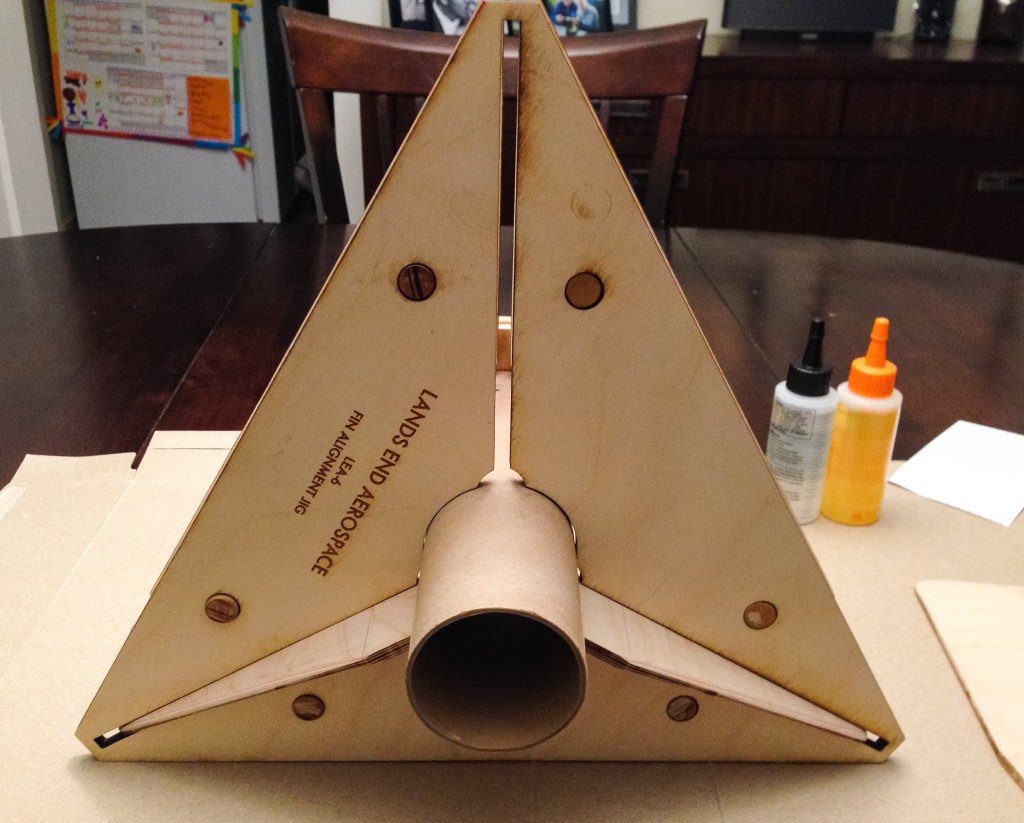

Here is a quick look at the fin alignment jig I made for my L2 rocket build. I wasn’t keen on the standard approach, where you eyeball down the fin to make sure it aligns with a printed template – that always seemed hokey to me. This was a relatively quick build. I drew it in Illustrator and cut it on the Epilog laser at TechShop. It’s made from 1/4″ birch plywood and some dowels I had lying around the shop. Total cost was about $5.

The jig has some nice features. First and foremost it ensures the fins are aligned in all planes: they are evenly spaced around the airframe, they are attached perpendicular to the airframe (no lean), and parallel to the rocket’s primary axis (no twist). I used this jig to tack them to the motor tube with epoxy. The triangular shape provided a nice way to rotate through each fin placement. There’s a small margin at each attachment point so I didn’t accidentally glue the fin to the jig with squeeze out. After these were dry, I removed the jig and followed up with solid internal fillets. I like this design and will use it again.

Here is a link to the Illustrator file in case anyone would like to modify and use it for their own purposes.

Leave a Reply