My last launch was almost four years ago. At the time I was newly certified at L1 and excited to get more mid- to high-power flights under my belt. It was July so Snow Ranch was in its off season. I drove down to Maddox Ranch to join the Tripoli Central CA club for a launch.

I was flying my LOC Forte on H power motors. It’s a very simple rocket that uses motor deployment for the recovery system – a glorified model rocket. The first flight of the day was on an CTI H225-11. It screamed off the launch pad and flew to an estimated 3,200 feet. The chute deployed at apogee and it landed nearby with very little drift on a calm day.

Feeling confident, and with another reload ready, I prepped the rocket for a second flight on a CTI 266H125-12. The take-off was clean, but just over a second into the flight the airframe shredded and the LCO jumped on the PA to warn about falling debris. Totally bummed, I collected the bits and pieces of my rocket which were scattered over a couple acres of dairy farm.

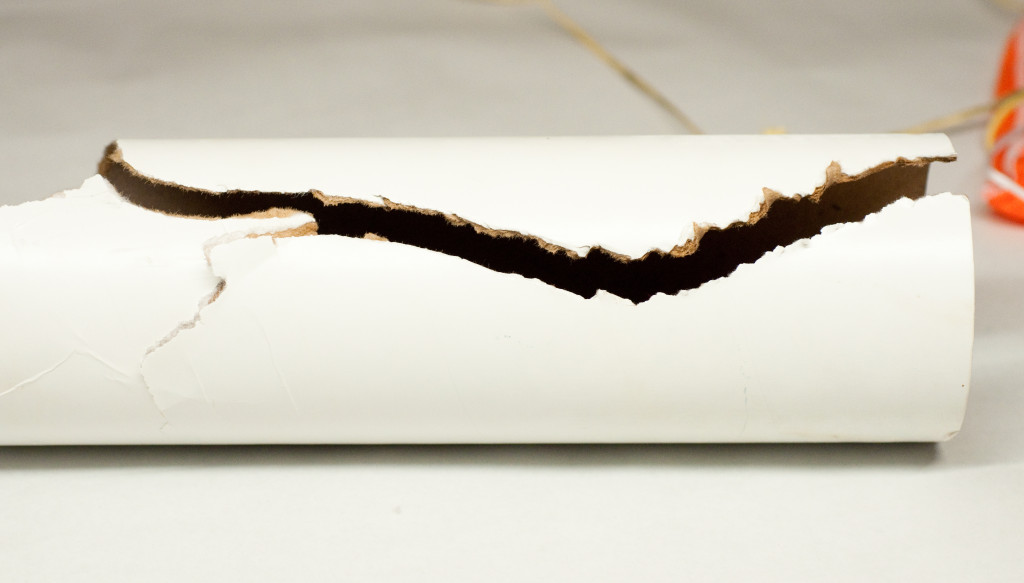

Upon initial inspection, I was confused. The airframe had zippered and torn into two pieces. The kevlar shock cord had snapped and the nomex chute protector had ripped straight through. Amazingly, the shock cord mount – nothing more than a simple epoxy joint inside the airframe – held fast.

The motor was still mounted in the rocket, so I couldn’t figure out what happened. I drove home trying to think through what went wrong. Later that evening, I unscrewed the motor retainer and was greeted by nothing more than the rear thrust ring and nozzle. The entire reload case was missing…nowhere in sight. After a few minutes scratching my head and examining what was left, it became obvious.

The rear o-ring had failed (see 8:00 on the photo). This blew the seal on the rear enclosure. At that pressure (still under thrust), the motor case separated from the rear enclosure. The motor case, no longer held in place by the thrust ring, flew straight through the body of the rocket, scorching the length of the motor tube, blowing off the nose cone and taking the recovery system with it. So, the parachute deployed at about 300 mph, causing the epic zipper and shock cord failure. I never did find the motor case.

Of course, it begs the question: why did the o-ring fail? Well, maybe it was cracked? But looking at the photo, you can see (at 2:00) a small piece of debris, maybe grass or a small leaf. I might have picked up some foreign object when I was reassembling the case after drilling out the delay. Either way, I take responsibility for the failure. I’m pretty sure that a close examination of the o-ring seal would have prevented this incident.

In the long run, I was able to repair the rocket with a coupler and new section of 4″ airframe tubing. I applied a fiberglass patch over the joint. After a good bit of sanding and paint it looks as good as new. I kept the zippered airframe and hung it above my workbench as a reminder to take my time and be careful with my work.

Leave a Reply